Artificial grass is widely used in modern landscaping, sports fields, and functional fitness spaces—but do you really know how artificial grass is made?

Despite its natural appearance, synthetic turf is created through a precision-engineered artificial grass manufacturing process involving high-performance polymers, extrusion equipment, and rigorous quality control in turf production. In this guide, we walk you through the step-by-step turf manufacturing process, from raw resins to export-ready artificial turf rolls.

1.Main Components of Artificial Grass: What Is It Made Of?

Before diving into how artificial turf is made, it’s essential to understand what artificial grass is made of—each layer contributes to performance, durability, and safety.

(1)Turf Yarn (Grass Fibers)

The visible blades of synthetic grass, known as turf yarn, determine the softness, color, rebound, and UV stability of the product.

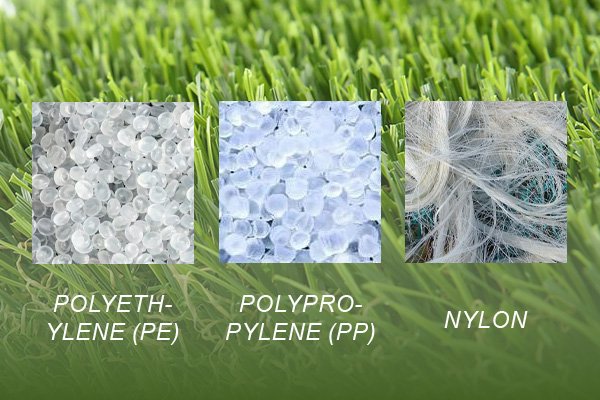

Materials used in turf yarn extrusion:

- Polyethylene (PE): Soft, flexible—perfect for landscaping turf and residential lawns.

- Polypropylene (PP): More rigid and economical—used for sports and decorative turf.

- Nylon: Exceptionally strong, resilient—ideal for golf or gym turf applications.

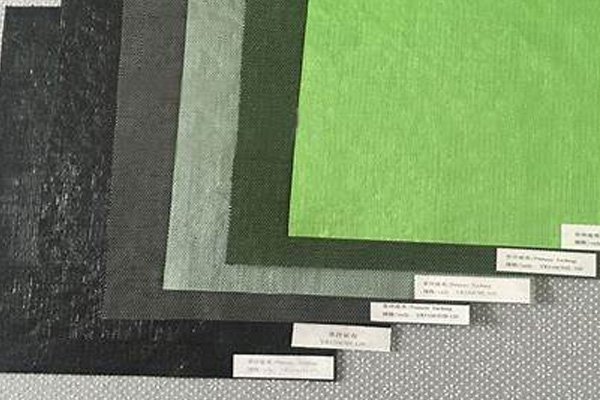

(2)Turf Backing System

- A dual-layer polypropylene fabric forms the turf’s foundation.

- It supports yarn insertion during tufting, maintaining structure and durability.

(3)Coating Layer (Turf Glue Backing)

- PU (polyurethane) or SBR (styrene-butadiene rubber) coatings are applied to secure the yarn.

- PU turf backing is preferred in premium, export-grade turf for its eco-friendly and flexible properties.

- Comparing PU vs SBR backing: PU is softer, longer-lasting, and more weather-resistant.

2.Step-by-Step Artificial Grass Manufacturing Process

Here is a simplified overview of the artificial grass production process inside a modern artificial grass factory:

(1)Raw Material Preparation

Plastic pellets (PE, PP, or nylon) are blended with performance-enhancing additives:

- UV stabilizers

- Anti-static agents

- Pigments (color masterbatch) for long-term vibrancy

- Optional antimicrobial agents

(2)Yarn Extrusion

- The plastic blend is melted and forced through specialized dies to form synthetic grass yarn.

- Common yarn types in turf manufacturing:

- Monofilament yarn: Realistic, resilient—used in high-performance turf.

- Fibrillated yarn: More affordable, used for low-traffic or decorative turf.

(3)Cooling and Texturizing

- Fibers are passed through water baths to cool.

- Then stretched, twisted, or crimped to simulate the appearance and bounce of real grass.

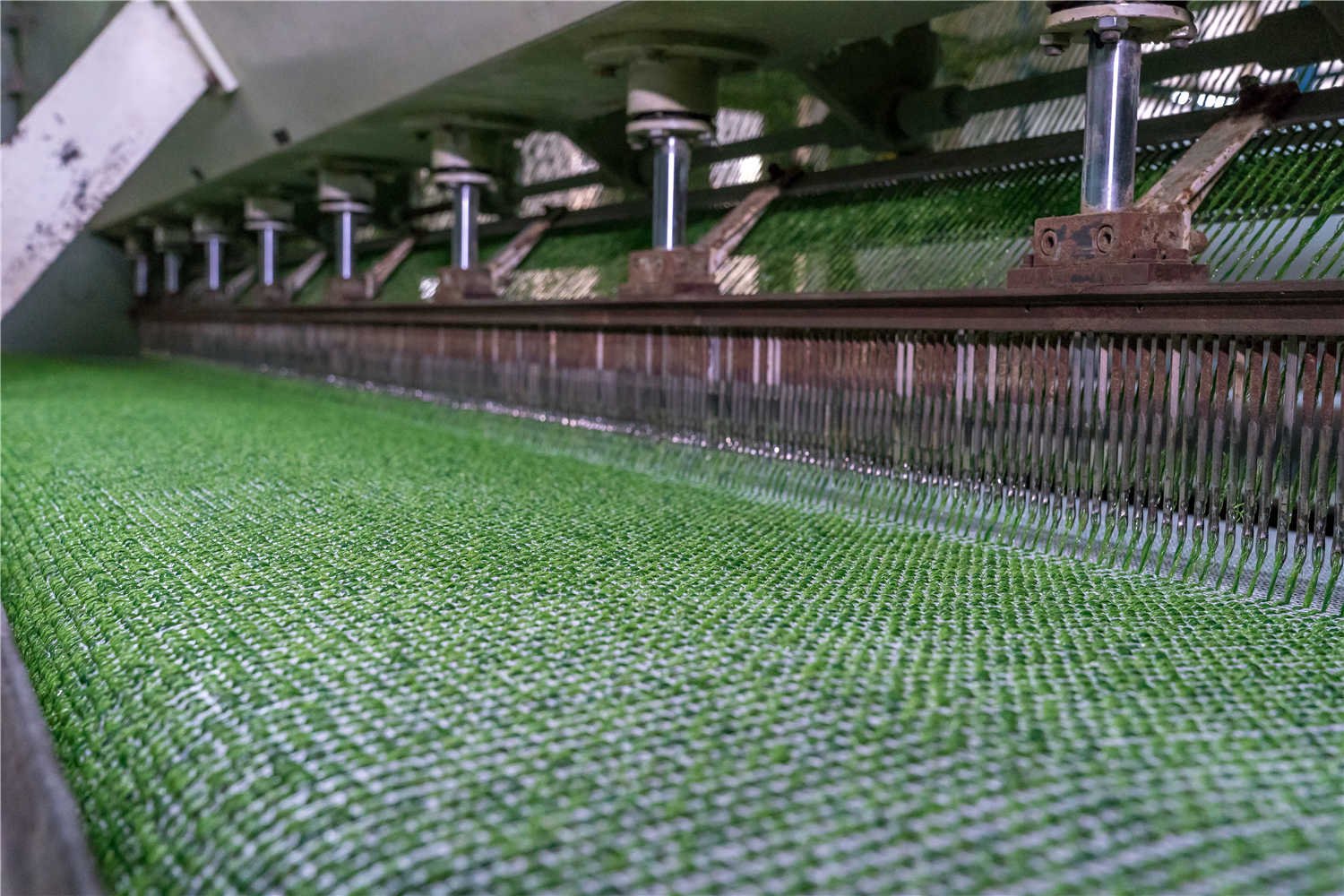

(4)Tufting (Stitching Yarn into Backing)

- High-speed tufting machines insert the yarn into the turf backing system, similar to carpet manufacturing.

- Stitch density, gauge width (e.g., 3/8″, 5/8″), and pile height determine product quality and application.

- Higher stitch rates result in denser, softer, and more durable turf

(5)Coating and Drainage

- A layer of PU or SBR adhesive is applied to secure yarn.

- Drainage holes are mechanically punched for water flow—crucial for outdoor installations like sports turf and playgrounds.

(6)Finishing and Quality Control

Each roll of turf undergoes detailed inspections for:

- Even tufting and fiber height

- Proper drainage pattern

- Strong glue adhesion

- UV stability and abrasion resistance

(7)Packaging and Shipping

- Turf rolls are trimmed, labeled, and shrink-wrapped.

- Export products are packed on pallets or in cartons with barcodes, hang tags, and spec sheets for international distribution.

3.Quality Control in Synthetic Turf Manufacturing

Top-tier turf products are only possible through strict quality control. Key checkpoints include:

- UV aging and weather resistance testing

- Consistency in yarn dtex and tufting density

- Adhesion testing for PU vs SBR backing

- Drainage hole alignment and punching precision

- International compliance: REACH, RoHS, EN71 certifications for health and environmental safety

4.How Manufacturing Choices Impact Turf Performance

| Manufacturing Feature | Performance Benefit |

| Monofilament vs Fibrillated | Monofilament is more realistic and bounces back better |

| PU vs SBR Backing | PU is stronger, lighter, and environmentally safer |

| High vs Low Density | Higher density improves comfort and visual appeal |

| Customized pattern machine vs high-speed tufting machine | Customized pattern machine can customize any pattern to showcase individuality; High speed tufting machine produces pure color lawns that meet the needs of the vast majority of production, with high cost-effectiveness |

5.Eco-Friendly Artificial Grass Manufacturing

Sustainability is now a key trend in modern synthetic turf production. Leading turf factories implement:

- Recyclable materials and lead-free components

- Water-based adhesives to reduce VOC emissions

- Energy-efficient extrusion systems

- Certifications like REACH, RoHS, and ISO9001 for both indoor and outdoor use

These advancements make eco-friendly artificial grass ideal for schools, rooftop gardens, pet turf, and environmentally regulated areas.

6.Conclusion: Why Knowing the Turf-Making Process Matters

Artificial turf is much more than fake grass—it’s the result of advanced polymer science, mechanical engineering, and sustainability innovation.

Understanding how synthetic turf is made helps:

- Buyers assess product quality and safety

- Installers and contractors recommend the right system for each project

- Turf brands highlight their manufacturing excellence

Looking for factory-direct artificial grass with full certifications and high-quality backing?

👉 Contact us now for technical specs, pricing, and free samples tailored to your turf project.